Research Article

Volume 3, Issue 7

Innovative Recycled PET 3-D Printed Foot Abduction Orthosis for Infant Clubfoot Treatment

Peredy Khwesa1*; Salsawit Tesfaye Yigrem2 ; Dagmawi Samuel Bekele3 ; Moy Tadesse Lemma3

1Materials Science Program/Department of Chemistry College of Natural and Computational Sciences, Addis Ababa University, P.O.Box 1176, Addis Ababa, Ethiopia.

2Department of East Africa Biodesign, St. Paul’s Hospital Millennium Medical College, University of Global Health Equity, Kigali, Rwanda.

3Wala ICT Consultancy and Advertising, P.O.Box 1000, Addis Ababa, Ethiopia.

Corresponding Author :

Peredy Khwesa

Email: khwesaperedy@gmail.com

Received : Jun 10, 2024 Accepted : Jul 04, 2024 Published : Jul 11, 2024 Archived : www.meddiscoveries.org

Citation: Khwesa P, Yigrem ST, Bekele DS, Lemma MT. Innovative Recycled PET 3-D Printed Foot Abduction Orthosis for Infant Clubfoot Treatment. Med Discoveries. 2024; 3(7): 1183.

Copyright: © 2024 Khwesa P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This paper presents the development of an innovative and cost-effective 3-D printed Foot Abduction Orthosis (FAO) for the treatment of infant clubfoot, specifically addressing the challenges faced in resource-constrained regions such as Ethiopia. The Ponseti technique of treating clubfoot, also known as congenital talipes equinovarus, necessitates the use of FAOs, which are often prohibitively expensive in low-resource settings.

Our methodology involved selecting recycled PET for the FAO fabrication due to its affordability and favorable material properties. We used SolidWorks, a dependable Computer-Aided Design (CAD) programme, to create the brace with the objective of reducing material consumption while maintaining both durability and precise dimensions. The 3-D printing process was optimized for cost efficiency, with a detailed cost analysis showing a production cost of approximately $5.254, which is expected to decrease with economies of scale.

The results demonstrate that the 3-D printed FAO includes essential features such as adjustable abduction angles, dorsiflexion capability, and adjustable foot width, enhancing both comfort and functionality. The brace design provides a significant static stretch to prevent recurrence due to fibrosis and contracture.

Our discussion highlights the economic feasibility of the 3-D printed FAO compared to commercial options, noting its potential for local manufacturing and customization. This approach addresses the economic and logistical barriers to effective clubfoot treatment in developing regions.

In conclusion, our study demonstrates that 3-D printing technology can create low-cost, functional FAOs, matching commercial options at a fraction of the cost. This technology holds promise for improving the accessibility and affordability of essential medical devices, ultimately enhancing treatment outcomes for children with clubfoot in resource-constrained settings. Future research will focus on testing these devices’ clinical efficacy and outcomes.

Keywords: Clubfoot; 3-D printing; Foot Abduction Orthosis (FAO); Infant orthopedic treatment; Low-cost medical devices; Resource-constrained settings.

Introduction

Globally, around 1-2 out of every 1000 newborns are affected with clubfoot, also known as congenital talipes equinovarus [1]. Characterized by a fixed position of cavus, forefoot adduction, and calcaneal equinovarus, clubfoot can be either idiopathic or linked to various syndromes and diseases [2]. In developed countries, prenatal ultrasonography and newborn screening facilitate early detection and prompt intervention [3].

Current treatment methods: The Ponseti method, involving sequential manipulation, casting, Achilles tenotomy, and bracing, is widely recognized as the most effective treatment for idiopathic clubfoot [4,5]. This method requires the use of a Foot Abduction Orthosis (FAO), commonly known as a “boots and bar” brace, to be worn continuously for the first three months and subsequently during naps and nighttime until the child reaches four years old [6].

Challenges in developing regions: In developing regions such as Ethiopia, managing clubfoot presents significant challenges. The incidence in some areas of East Africa is up to 8 per 1000 births, double that of affluent countries [7]. High costs and limited access to treatment often result in permanent disabilities if untreated [8]. While FAO braces are relatively affordable in developed countries, their costs can be prohibitive in lowresource settings, ranging from $60 in Africa to $200 in Latin America [9,10]. Ethiopia faces significant challenges in terms of the availability and affordability of effective treatment options [11].

Innovative 3-D printing solutions: Recent advancements in 3-D printing technology offer promising solutions to these disparities. Open-source 3-D printers have significantly reduced production costs, making manufacturing more accessible [12]. These printers, which cost a few hundred dollars, can produce most of their components and have been used to create essential items in disaster relief situations [13]. The ability of 3-D printing to produce medical and scientific equipment at a lower cost makes it a viable option for creating affordable FAO braces in resource-limited areas [14]. With the hope of giving patients in Ethiopia and other underdeveloped areas a more affordable and easily accessible alternative, this research investigates the potential of 3D printing clubfoot braces. By leveraging distributed manufacturing, we aim to improve access to essential medical equipment, thereby enhancing the effectiveness of treatment for children with clubfoot in resource-constrained areas.

Materials and methods

Material selection: Recycled PET from bottles was chosen for the FAO fabrication due to its affordability and desirable properties, such as high strength, modulus, and stiffness. Additives in the PET manufacturing process also provide UV blocking and oxidation scavenging, enhancing the material’s durability and reliability. With a melting point of around 250-260 degrees Celsius, it is practical for 3-D printing and improves robustness in daily use.

Design and development: A trustworthy and powerful CAD programme, SolidWorks was used to create the clubfoot brace. While keeping strength and dimensional correctness in mind, the design minimised material use and overhangs. Key design features included adjustable abduction angles, dorsiflexion capability, and width adjustments between the feet, ensuring comfort and proper positioning as the child grows. This was supported by a literature review represented in Table 1 below.

Table 1: Design criteria for fabrication of an FAO derived from literature review.

| Design criteria | Description | References |

|---|---|---|

| Adjustability of Abduction Angle | For feet that are afflicted, the ideal foot pad or boot rotation is 60–90 degrees, whereas for feet that are unaffected, it should be 20–45 degrees. |

[3,15] |

| Dorsiflexion Capability | The brace should allow dorsiflexion of the feet to an angle between 0-20 degrees. | [3,15] |

| Adjustable Foot Width | The brace should enable adjustment so that the heels are positioned at a distance equal to the width of the infant’s shoulders. |

[3,15] |

| Independent Foot Movement | Maintaining the required outward correction angle should be possible with independent movement of each foot. |

[16] |

| Removable Footpads | The footpads should be detachable for easy application and big enough to suit children's shoes. | [3,15] |

3-D printing process: The brace components were fabricated utilizing PrusaSlicer 2.7.4 software, a standard choice for creality Ender 3 v2 and Prusa Mk3 13 3D printers. The printing process adhered to precise parameters: a 0.2 mm layer height, 1 mm shell thickness, 50% gyroid infill density, a print speed of 40 mm/s, and a bed temperature of 80°C. Notably, the print temperature was adjusted to a higher setting of 260°C to accommodate the material and optimize print quality.

Cost analysis: A detailed cost analysis was conducted, considering labor, filament, and electricity costs. The total production cost of the brace was calculated using modified methodologies from Laplume et al. (Equations 1-5), Table 2.

Results and discussions

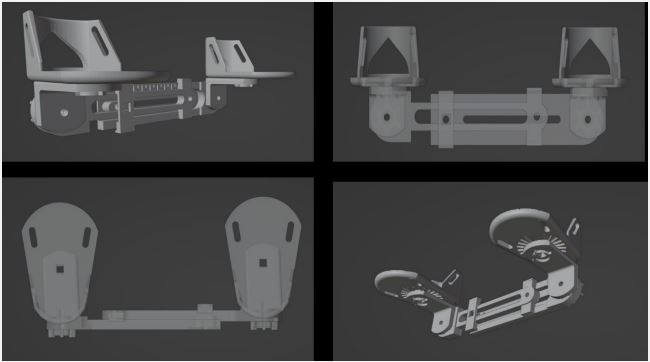

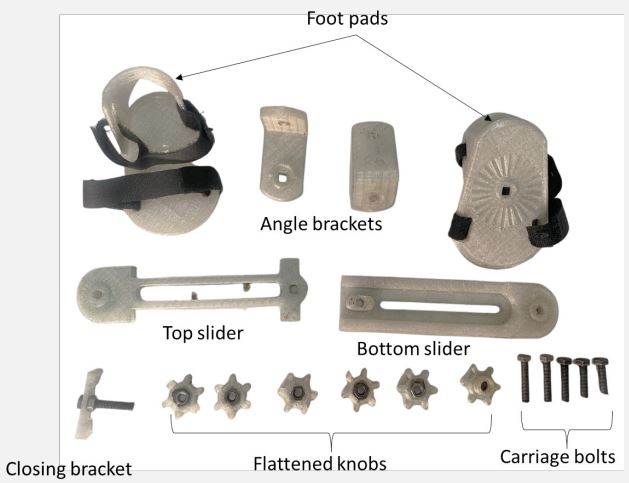

Biomechanics and functional design: The final design of the clubfoot brace included 13 printed components, with their masses, printing times, and estimated material costs detailed in the results and discussion section Tables 4,5. The pictures of the CAD designs are presented in Figure 1, whilst those of the 3D printed FAO are depicted in Figures 2 and 3. The non-printed components were individually itemised, as seen in Table 3. The brace’s total material cost amounted to around $1.247.

Table 2: Criteria for cost calculations [17].

| Equation | Description | Formula | Variables |

|---|---|---|---|

| Equation 1 | Aggregate expenditure for man- ufacturing the brace |

C = CE + Cc + CL + Ch | C: Overall expense ($), CE: Power cost ($), Cc: Consumption cost of filament in dollars, CL: Wage expense ($), Ch: Price of non-printed hardware machined parts ($) |

| Equation 2 | Electricity expenses | CE = E Cu | E: Total energy usage (kWh), Cu: Unit energy cost ($/kWh) |

| Equation 3 | Aggregate energy consumption | E = Pp t + Ew | Pp: kW average power usage during printing; t: print time in hours; Ew: kWh energy con- sumption for printer warming |

| Equation 4 | Filament consumption cost | Cc = mp Cf | mp: Kilogrammes of filament utilised in the print, Cf: Cost per kilogramme of filament |

| Equation 5 | Cost of labor | CL = w t | Time of print (hr) and hourly compensation ($/hr) |

| Cost of non-printed hardware | Ch | Ch: Price of non-printed hardware machined parts ($) |

Table 3: Bill of quantities for non-printed hardware.

| Component | Quantity | Cost |

|---|---|---|

| #8-32 1" bolt, medium carbon alloy steel | 2 | $0.18 |

| #8-32 1.25" bolt, medium carbon alloy steel | 1 | $0.22 |

| #8-32 0.75" bolt, medium carbon alloy steel | 3 | $0.17 |

| #8-32 hex nut, 18-8 medium carbon alloy steel | 6 | $0.05 |

| Total Cost | $0.62 |

The brace design incorporated customisable breadth, dorsiflexion angles, and autonomous footpad motion, therefore improving comfort and guaranteeing a suitable fit as the infant develops. The design ensured that the feet were positioned at a 70o angle of hip abduction and a 15o angle of dorsiflexion. This positioning created a static strain on the ligaments located on the back and inner side of the hindfoot. Adherence to wearing the brace is essential in order to avoid the reoccurrence caused by the development of fibrosis and contracture in these tissues [18].

Economic feasibility: The cost analysis compared the 3-D printed brace with other existing FAOs, highlighting its affordability and potential for local customization (Table 6). The opensource 3-D printed orthosis matches the features of commercial options at a significantly reduced cost.

Comparison with existing FAOs: The fabricated FAO was compared to existing 3D printed brace as described by [19].

Table 4: Bill of quantities for 3D printed hardware.

| Component | Quantity | Print Time (hrs:min) | Mass (gm) | Cost |

|---|---|---|---|---|

| Knob (Flat) | 5 | 0:08 | 5 | |

| Knob (Raised) | 1 | 0:08 | 4.5 | |

| Closing Bracket | 1 | 0:09 | 5 | |

| Angle Bracket | 2 | 1:00 | 27 | |

| Bottom Slider | 1 | 1:12 | 50 | |

| Top Slider | 1 | 1:13 | 50 | |

| Foot Pad | 2 | 2:10 | 63 | |

| Total | 13 | 9:42 | 314.5 | $0.63 |

Table 5: Cost estimation values adapted from [19].

| Fixed Inputs | Value | Variable Inputs |

Lower limit |

Upper limit |

|---|---|---|---|---|

| The total mass of the PET filament consumed |

0.315 kg |

Costs per unit of energy |

$0/kWh | $0.006 /kWh |

| The calculated amount of power consumed by the printer during the print. |

50W | Cost per unit of filament, C |

$0/kg | $1/kg |

| The total energy re- quired to warm the 3D printer bed to 80oC, Ew |

2 Wh | Wages, w | $0.00/ shift |

$4/shift |

| Total time required to 3D print, t |

9.75h | |||

| Cost of additional hardware, Ch $0.62 |

||||

Table 6: Comparative analysis of 3D printed fao with market offerings.

| FAO Type | 3-D Printed Brace | Ponseti AFO [20] | Steenbeek [21] | Miraclefeet [22] |

|---|---|---|---|---|

| Cost | $5.254 with realistic labor, elec- tric, and PET material costs. |

|||

| Selling Price | Expected to range between $20 and $30 |

~$370 | >$300 | $50 |

| Description | An affordable brace made using open-source hardware and intended for 3-D printing. |

The typical clubfoot commercial or- thotic consists of two boots connected by a lateral bar that may be adjusted. |

A modified Ponseti FAO that permits somewhat autonomous foot mobil- ity. |

An affordable orthotic designed specifically for use in poor na- tions by the Stanford team. |

| Locally Manufactured | Indeed, using diffused 3-D printing |

No | No | Yes, with regional resources and craftspeople. |

| Adjustable Abduction Angle |

Yes | Yes | Yes | Indeed, that may be accomplished by manually modifying the shape of the bar. |

| Dorsiflexion Capability | Yes | Yes | Yes | Yes |

| Adjustable Foot Width | Yes | Yes | Yes | No |

| Independent Foot Movement |

Yes | No | Yes | No |

| Removable Footpads | Yes | Yes | Yes | No |

In Ethiopia and similar regions, the 3-D printed FAO presents a viable and cost-effective solution for treating clubfoot. Its low production cost, local manufacturing capability, and functional advantages make it an ideal choice for overcoming the economic and logistical barriers that hinder access to effective clubfoot treatment. By leveraging 3-D printing technology, healthcare providers can enhance the availability and affordability of essential medical devices, ultimately improving treatment outcomes for children with clubfoot in resource-constrained settings.

Conclusion

The study demonstrates that 3-D printing technology can be utilized to create a low-cost Foot Abduction Orthosis (FAO) for children with clubfoot. The 3-D printed orthosis matches the physical features of commercial options but at a significantly lower cost and allows for enhanced local customization. Further investigation is required to evaluate the effectiveness and results of these devices in clinical environments. With the continuous progress of 3-D printing technology and the increasing availability of materials, it presents a hopeful and economically efficient option for supplying FAOs and other orthotic devices in underdeveloped areas.

Declarations

Ethical approval and consent to participate: No ethical approval was required nor sought during this work.

Consent for publication: All authors give their consent for publication.

Availability of data and materials: The data can be obtained by contacting the corresponding author upon reasonable request.

Competing interests: The authors declare no conflict of interest.

Funding sources: This work received no support from any funding agency.

Author contributions: PK: Conceptualization, Methodology, Writing - original draft, Formal analysis, Project administration, Writing - review & editing, Supervision. STY, DSM and MTL Conceptualization, Design, review and editing.

Acknowledgement: The Biomedical Smart lab at AAiT, Addis Ababa University; The National Biomedical Competition, Ethiopia.

References

- Dobbs MB, Gurnett CA. Update on Clubfoot: Etiology and Treatment. Clin Orthop Relat Res. 2009; 467(5): 1146-53.

- Ponseti IV. Treatment of congenital club foot. J Bone Joint Surg Am. 1992; 74(3): 448-54.

- Global HELP. Clubfoot: Ponseti Management. 2024. Available from: https://global-help.org/products/clubfoot_ponseti_management/.

- Bergerault F, Fournier J, Bonnard C. Idiopathic congenital clubfoot: Initial treatment. Orthop Traumatol Surg Res. 2013; 99(1 Suppl): S150-159.

- Chen H, Clubfoot. In: Chen H, editor. Atlas of Genetic Diagnosis and Counseling. New York, NY: Springer; 2016; 1-10. Available from: https://doi.org/10.1007/978-1-4614-6430-3_46-2.

- Radler C. The Ponseti method for the treatment of congenital club foot: review of the current literature and treatment recommendations. Int Orthop. 2013; 37(9): 1747-53.

- Morcuende JA, Dolan LA, Dietz FR, Ponseti IV. Radical reduction in the rate of extensive corrective surgery for clubfoot using the Ponseti method. Pediatrics. 2004; 113(2): 376-80.

- Smythe T, Mudariki D, Kuper H, Lavy C, Foster A. Assessment of success of the Ponseti method of clubfoot management in subSaharan Africa: A systematic review. BMC Musculoskelet Disord. 2017; 18: 453.

- Pirani S, Zeznik L, Hodges D. Magnetic resonance imaging study of the congenital clubfoot treated with the Ponseti method. J Pediatr Orthop. 2001; 21(6): 719-26.

- Rijal R, Shrestha BP, Singh GK, Singh M, Nepal P, et al. Comparison of Ponseti and Kite’s method of treatment for idiopathic clubfoot. Indian J Orthop. 2010; 44(2): 202-7.

- Grimes CE, Holmer H, Maraka J, Ayana B, Hansen L, et al. Costeffectiveness of club-foot treatment in low-income and middleincome countries by the Ponseti method. BMJ Glob Health. 2016; 1(1): e000023.

- Gershenfeld NA. Fab: The coming revolution on your desktop--from personal computers to personal fabrication. Basic Books (AZ). 2005.

- Bowyer A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Printing and Additive Manufacturing. 2014; 1(1): 4-5.

- Jones R, Haufe P, Sells E, Iravani P, Olliver V, et al. RepRap-the replicating rapid prototyper. Robotica. 2011; 29(1): 177-91.

- Desai L, Oprescu F, DiMeo A, Morcuende JA. Bracing in the treatment of children with clubfoot: past, present, and future. Iowa Orthop J. 2010; 30: 15-23.

- Garg S, Porter K. Improved bracing compliance in children with clubfeet using a dynamic orthosis. J Child Orthop. 2009; 3(4): 271-6.

- Laplume A, Anzalone G, Pearce J. Open-source, self-replicating 3-D printer factory for small-business manufacturing. The International Journal of Advanced Manufacturing Technology. 2015; 85(1): 633-42.

- Zhao D, Liu J, Zhao L, Wu Z. Relapse of Clubfoot after Treatment with the Ponseti Method and the Function of the Foot Abduction Orthosis. Clin Orthop Surg. 2014; 6(3): 245-52.

- Savonen B, Gershenson J, Bow JK, Pearce JM. Open-Source Three-Dimensional Printable Infant Clubfoot Brace. JPO: Journal of Prosthetics and Orthotics. 2020; 32(2): 149.

- Clubfoot Shoes Mitchell Ponseti® AFO standard with Ponseti® Abduction Bar - Ponseti Klompvoet. 2024. Available from: https://www.ponseti-clubfoot.com/product/ponseti-afo-standard-with-bar/.

- Global HELP Steenbeek Brace For Clubfoot. 2024. https://globalhelp.org/products/steenbeek_brace_for_clubfoot/.

- Miracle Feet. Providing Clubfoot Treatment to Children. 2024. https://www.miraclefeet.org/.